8 at the middle of the fin leading edge corresponds to the location of the first flat tube. As expected, large Nusselt numbers are obtained at the leading edge of the test fin. The location of the tubes are dark areas in figs. Local fin Nusselt number for arrangement with flat tubes, (a) without VGs, (b) with VGs. The experiments were performed using air ranging in Reynolds number from 9,400 to 28,200, where the Reynolds number here is defined as Re = U♲H/ν.įig. Furthermore vortex structures behind the generators were visualized by a flash light sheet method using smoke as a tracer supplied at upstream. Then the streamwise and spanwise local heat transfer coefficients hx, hz = qw/(t wx-t bx) were obtained. Bulk temperatures of the flow t bx were obtained by adding to the initial temperature increments of temperature equivalent to the total amount of heat generated between the starting point of heating and the measurement point. The other strips are used for measurement of streamwise local wall temperatures. One strip is set with the blades, and allowed to move laterally to obtain the details of the spanwise wall temperature profile. Seven strips downstream of the blades are provided with nine thermocouples each for the spanwise temperature distributions. The wall surface temperatures t wx were measured by means of copper-constantan thermocouples with ϕ 70 μ m soldered on the back of the foil.

The heat transfer surfaces, the top and bottom inside surface of the duct, were produced by attaching stainless-steel foil of 30 μm thickness divided into nineteen strips across the flow direction the surface heat flux qw was maintained uniform under direct current. Spanwise pressure distributions were measured using ϕ 0.4mm static pressure taps installed laterally at discrete intervals downstream of the generators, while pressure drop was determined from the hydraulic pressure gradient lines obtained from measurements of the pressure upstream and downstream of the blades. Experimental apparatus and arrangement of vortex generators

#Vortex account generator generator

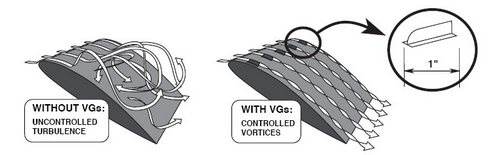

Furthermore, decreasing flow speed in the channel increases the effectiveness of the vortex generator according to PEC results.Fig. Furthermore, PEC results showed that the most feasible geometric design of PRVG winglet for the fin-tube heat exchanger is H/d=0.161 and α r=20°. The influence of ramp angle on thermo-hydraulic performance was more significant compared to ramp height. Results showed that overall heat transfer on the entire channel wall increases up to 43.66% for Re=5000 by H/d=0.196 and α r=35°. Results were compared with the flat smooth fin surface (baseline case). Flow characteristics were also investigated for elucidating the underlying physics of enhancement heat transfer by the PRVG winglet. Nusselt ( Nu) number, friction factor and Performance Evaluation Criterion ( PEC) were comprehensively examined quantitatively. RANS equations were solved using ANSYS Fluent by using SST k-ω turbulence model. Numerical computations were carried out under turbulent flow conditions (5000≤ Re≤20000). Normalized ramp height ( H/d=0.196 and 0.161) and ramp angle ( α r=20° and 35°) were examined as the geometric parameter. In this study, effect of newly proposed punched triangular ramp vortex generator ( PRVG) on heat transfer performance for a fin-tube heat exchanger was investigated numerically. Existence of the vortices in a flow field strongly affects the heat transfer.

0 kommentar(er)

0 kommentar(er)